Why Do We Need Batch Production and Batch Numbers in Pharmaceutical Manufacturing?

A batch, according to the US FDA, means a specific quantity of a drug or other material that is intended to have uniform character and quality, within specified limits, and is produced according to a single manufacturing order during the same cycle of manufacture. A batch therefore is a specific amount of an API or other material, like an excipient, that is processed in one or more ways so as to demonstrate homogeneity of the product.

What is a Batch Number

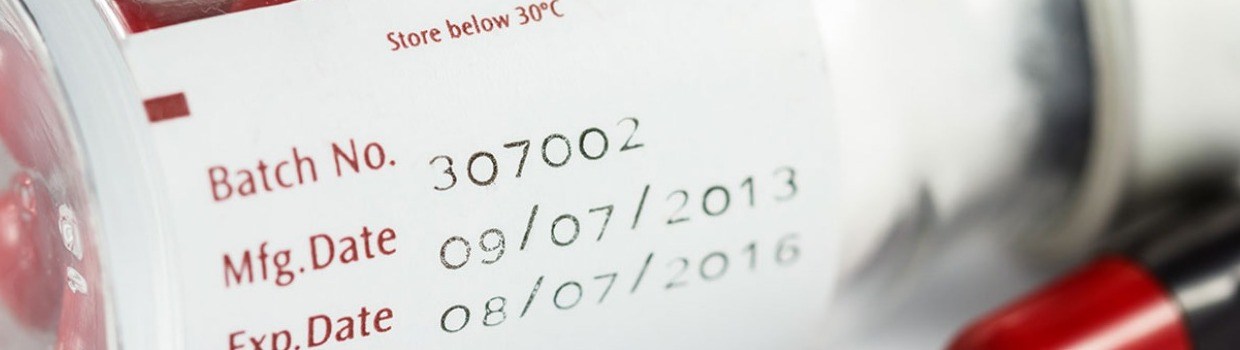

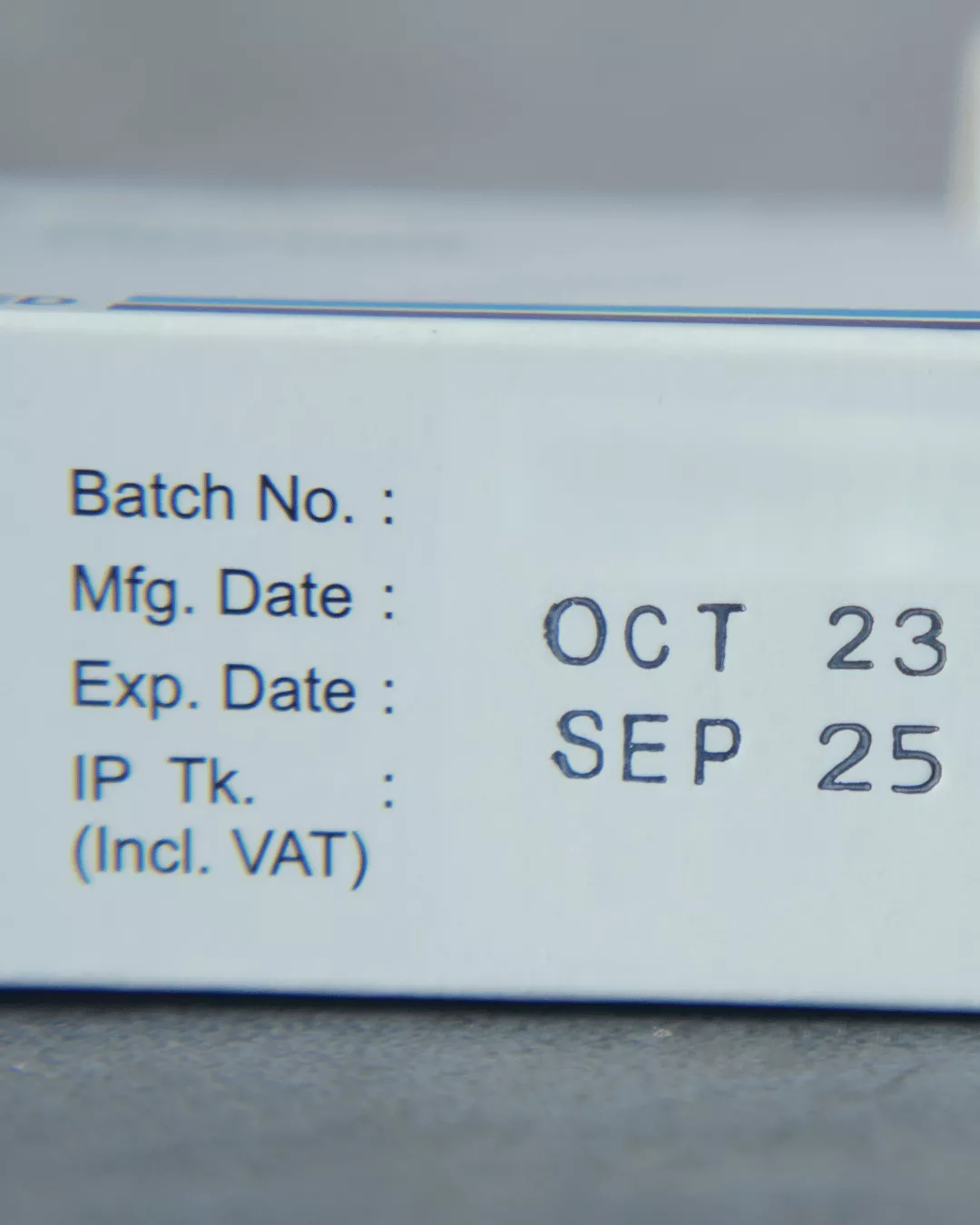

A batch number is a designation that is printed on the drug label that allows the history of its production to be traced. This includes not only identification of the specific batch produced, but all relevant issues of control and manufacturing particulars should also be traceable from the batch number.

It is important therefore that all batches of tablets or capsules are given an identifying number immediately after production from the rotary tablet press (or any type of pill press) or capsule filler and before progressing to the packaging stage.

Sign Up to Our Newsletter

Importance of the Batch Number for Pharmaceutical Companies

Batch number is also referred to as “lot number”. Recording of the batch and batch number typically starts at the manufacturing plant. Batches should be maintained and recorded according to:

- Quantity: The total number of units (e.g., tablets, capsules, packages) produced in the batch.

- Manufacturing Cycle: The time frame during which the batch was produced, including start and end dates.

- Expiry Date: The date after which the product should not be used; based on stability data and regulatory requirements.

- Weight of the Active Ingredient: The amount of the main therapeutic component in the product, often listed per unit (e.g., per tablet).

- Excipient(s): The inactive substances in the formulation, such as fillers or tablet binders, which support the delivery of the active ingredient.

The importance of a batch number is especially clear in drug manufacturing rules in New Zealand. If there's ever a concern about a drug, its entire production history must be traceable through the batch number.

Legal and Regulatory Requirements for Batch Manufacturing

According to the New Zealand Ministry of Health:

-

Each drug batch must be assigned a unique identifying number.

-

This number must:

-

Be included in batch documentation.

-

Be printed clearly on the product label (usually during packaging).

-

-

A sample from every batch must be stored for the product’s shelf life plus one year.

What Goes Into A Batch Record

Each batch record must include:

-

The exact amount of active ingredient used.

-

A list of all excipients in the formula.

-

The complete product formula.

-

All steps followed during production.

Responsibilities in the Manufacturing Plant

For every drug or batch produced:

-

A separate batch record is required.

-

The plant operator must measure and record active ingredients accurately.

-

After production:

-

All equipment must be cleaned and sanitized.

-

This prevents contamination when starting the next batch.

-

The QA team checks that cleanliness standards are met.

-

Traceability and the Use of Batch Numbers

With a batch number, manufacturers can:

-

Track the entire production process.

-

Check the manufacturing and expiry dates.

-

Verify batch-specific pricing.

-

Prove compliance with regulatory guidelines.

These practices aren’t just formalities; they're essential for maintaining drug quality, safety, and compliance. By following these guidelines, pharmaceutical manufacturers can respond quickly to any concerns and ensure every product meets the required standards.

Importance of the Batch Number in Pharmaceutical Regulatory Compliance

The batch or lot number is a key part of product labeling and should be clearly printed on all bottles, packs, and cartons as required by local health authorities. This number is critical for traceability, especially in cases where a product needs to be recalled or if there's a quality issue with a specific batch.

Need help with your tableting pressing equipment? Contact LFA Machines today and our team can assist you with the tools and machines you need to produce your tablets efficiently.