Importance of Punch Length and Cup Depth

Manufacturing tablets that have uniform shape, size, thickness and hardness requires consistency between the lengths of tablet press punch dies. This article briefly describes how the punch length can be measured correctly and the importance of cup depth tolerance. Issues of wear and tear are also briefly discussed.

In using rotary tablet press punches it is important that the punches are of the same length. Small variations in punch length will affect the uniformity of the tablet product in terms of weight, thickness and hardness. If the punch lengths are not known, defects in tablets may be wrongly attributed to other causes. It is therefore important to conduct regular maintenance and inspection to ensure that all punch lengths and cup depths are uniform.

Length

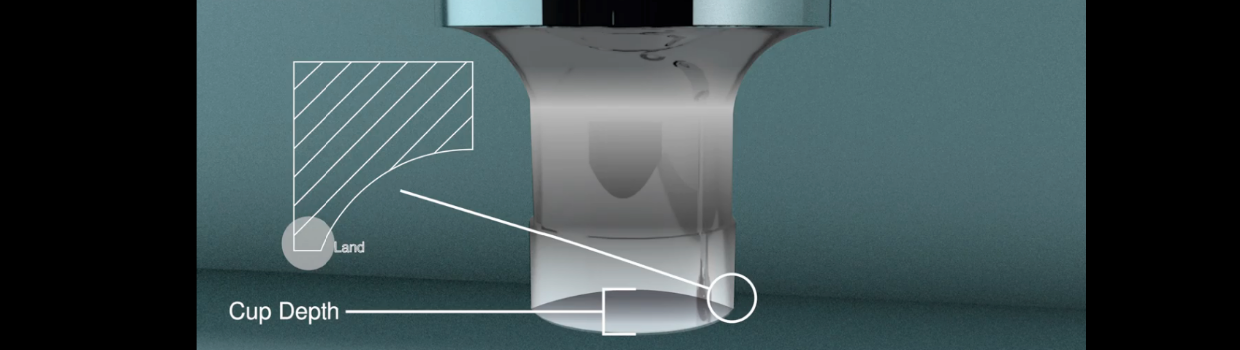

Tablet punches are manufactured with consistent length as measured by the distance from the head flat to the lowest measurable area of the punch cup (Figure 1). The cup depth as well as the overall length – from the head flat up to the punch tip is shown in Fig. 1. .

The punches in a tablet machine should all be similar in length; differences in the length of punches on the same machine will lead to variations hardness, thickness and weight of the tablets that are produced. It is therefore essential that the working length of the punches are closely matched. The lengths should not vary by more than a standard 0.002 inch (0.05mm). In other words, in a set of punches, the difference between the longest and the shortest working lengths should be a maximum of 0.002 inch. It is recommended that the punches are regularly checked to ensure that the lengths do not exceed the specified tolerance. During inspection, the upper punch and lower punch should be inspected separately.

It is also important to measure the length correctly. The length should not be obtained by deducting the cup depth from the overall length, as this leads to inconstant results and may show that the tools are out of specification. The correct way of measuring the length of punch is to use a digital indicator that is mounted on a steel post and fixed to a granite base. The basic equipment costs less than $500 and provides the same accuracy as that of equipment that costing much more.

Whatever equipment is used, care should be taken if there is embossing on the punch cup. In such cases the working length should be measured from the lowest area of the cup which can be accessed with the point of the indicator. Measurements should be made from the same lowest point on each punch, to ensure consistency between measurements.

When new punches are supplied, some punch manufacturers provide a report showing the consistency between punch lengths. In such a report Such a report pairs the upper with the lower punch, longest to the shortest and are then numbered accordingly. Matched sets are ideal as they can provide consistency in terms of the hardness and thickness of the tablet and the report would be helpful during setup.

It is important to note that the lower punch length is more important than that of the upper punch. The reason behind this is that the length of the lower area determines the uniformity of the filling in the die. Changes in the amount would affect the weight and hardness of the tablet.

Sign Up to Our Newsletter

Cup Depth

In measuring the cup depth, one should start measuring from the tip edge of the punch to the lowest theoretical point of the cup. Some configurations have a different depth; examples are those tablets with scalloped edges. The cup determines the appearance and configuration of the tablet’s face. The tablet sidewall is the space between the two tablet faces that is created by the die. It is also known as the tablet band or tablet gate. Although the sidewall is not measured or inspected, it is still important in terms of the tablet’s appearance and during manufacturing process. Preferably, the sidewall width is proportioned to the tablet’s thickness, as a tablet that has an excessive sidewall would appear thicker creating the idea that it would be harder to swallow. An excessive thick wall would also make the press exert greater force in ejecting the tablet.

The sidewall width depends on the hardness, thickness and weight in relation to the cup depth. As the tip of the punch wears out, the cup depth decreases and the sidewall starts to thicken. Thus in comparing two tablets of equal weight and hardness, the 1st tablet is made with a shallow cup whereas the 2nd cup is made up with a deep cup. The 1st cup has a thicker wall but it is thinner than the deep cup tablet. Because of the sidewall’s thickness, it creates the illusion that it is thicker and thus visually undesirable. The shallow cup’s sidewall can also cause problems especially during film coating as erosion may occur on the sharp corners where the tablet’s radius and the sidewall meets.

Many press punches have a cup depth tolerance of 0.003 inch, which is widely accepted by the tablet compression industry and is followed by tooling manufacturers around the world. [Tableting Specification Method]. Although the 0.003 inch is widely accepted, it is not applicable with some applications especially if the diameter of the tablet is different from that which the company is currently manufacturing.

An example would be if the manufacturing company has to produce Schedule II drugs with a depth of 0.010 inch. The standard is 0.003 inch. If one complies with the standard, there would be a deviation of up to 60 percent of the desired cup depth. Another would be when one is manufacturing vitamin supplement tablets. The deepest cup would be 0.060 inch. In following the standard, there would be a deviation of 10 percent. There is a huge difference considering that the one we are using is a Schedule II or a small diameter size tablet.

In order to remove the deviation, it is important to specify the tolerance as the % of the desired cup depth. Example, in specifying a tolerance range of 20% of the desired cup depth for the 1st cup, changes the range from 0.007 – 0.013 inch to 0.009 – 0.011 inch. To inspect the cup depth, one can use the digital indicator mounted on a steel post to measure.

Overall Length

The overall length is least likely to consider in a punch. The overall length is the distance from the punch tip to the head flat. It is the reference dimension that is made up of two or more important dimensions – working length and cup depth. As both the working length and cup depth have their own tolerance, assigning tolerance to the overall length is not necessary. As long as the tolerance for the other two is working, one no longer needs to inspect the overall length, as it will remain consistent. That said the overall length of the lower punch is important especially when it comes to setting the punch height to ensure uniformity of the tablet as well as reduce the probability of tablet damage. If it is standard procedure to check and inspect the overall length, then one can use the regular tools in inspecting the cup depth and working length to measure.

Wear and Tear

With regular use, punches would wear, especially in the tip area, which reduces the cup depth. This would then affect the overall length of the punch although it will not affect the working length. Wear in the head flat can also affect the overall length as well as the working length; however, it does not affect the cup depth. Regular maintenance of the tip, head and cup face can also affect the punch length. Using abrasive materials for cleaning, stiff brushes and bobs can also deepen the cup and alter the working length.

Wear can also occur at the narrow flat area located at the punch tip’s perimeter, in that when exposed to abrasives, the tip becomes thin and sometimes razor sharp causing a J-hook. J-hook usually causes tablet capping as well as lamination. To restore the land, use a soft cotton wheel and a polishing compound. Advantage would be that it prolongs the life of the punches; the disadvantage would be that it reduces the overall length and cup depth.

Summary

Uniformity is important to ensure consistency and smooth operation of the tablet presses. The most important part would be the working length followed by the cup depth and the overall length. In addition, to improve the uniformity of the tablets, it is important to obtain a matching report that will be useful as a guide for tablet consistency.