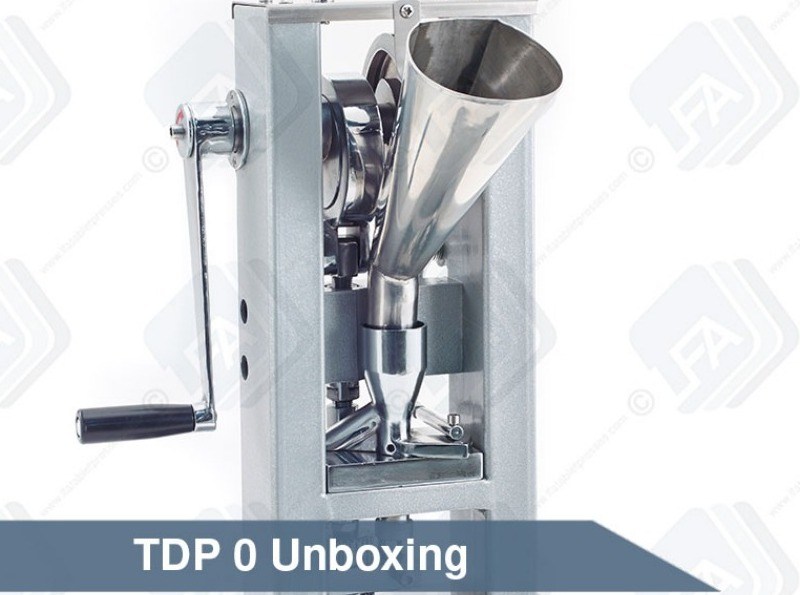

TDP 0 卓上打錠機

TDP 0打錠機は、電力を必要とせずに直径10㎜、厚さ6㎜までの丸錠を打錠できる高度な手動操作式打錠機です。そのコンパクトな寸法のおかげで、軽量で手動操作式のTDP 0は、野外調査や現地で実施される作業を含め、携帯性と利便性を求める応用分野で人気があります。

Connect with Our Team

If you have a question or would like more details on the TDP 0 卓上打錠機, please complete the form below and someone from our team will be in touch with you soon.

交換可能なダイと使い勝手の良い圧力15Knを備えるTDP 0は、大学、病院、研究所、並びに医薬品、食品及び化学産業の関連機関での使用のために高品質な錠剤を簡単に製造できます。さらに、少量の錠剤しか必要ない方やその場しのぎで錠剤が必要な方に適しています。

一目でわかる主なメリット:

- 小型軽量で電力を必要とする打錠機よりもはるかに携帯性に優れている

- 高度エンジニアリングが、電気なしで高品質な錠剤を簡単に製造させてくれる

- 最大直径10㎜までの丸錠を製造可能

- 使用や保守のしやすさ

- 交換式ダイ

- ランニングコスト不要

- 幅広い応用に適する作り込まれた信頼できる機械

特長

TDP 0の印象的な特徴は、軽量かつコンパクトで携帯しやすく外部からの電力がなくても高品質な錠剤を製造できる優れた設計です。手動を圧力に変えるとても効率的な構造を持ち電気不要でも動作に全く問題ないTDP 0は、シンプルでも低ランニングコストで効果的な錠剤化ソリューションを必要とするあらゆる応用にふさわしい打錠機です。

定期的に潤滑油を垂らす以上の費用を負担することがないTDP 0は、非常にコスト効率が高いです。幅広いダイに対応でき、適切に圧縮した錠剤を高い基準で製造できます。

使用時のTDP 0 打錠機

TDP 0を使用する前、たくさんの努力が必要だと考えていたかもしれませんが事実とまるで懸け離れています。ダイを設置して機械に粉体を充填したら、ただハンドルを回転させるだけです。適度な量の力をかけるだけで素晴らしい錠剤を作れます。1分で20錠出すのは簡単です。少し練習すれば、1分ですぐ40錠出せます。

錠剤の厚さや硬さを調節したいならば、ほんの数ステップで簡単にできます。

本当にそれだけのことです。機械自体の重量は約24㎏で、それほど難しくなく持ち上げるのに十分小型でコンパクトです。何百㎏もある多くの業務用大型機械と比較すると、TDP 0は、非常に軽量です。確かに、必要に応じて、病院、研究所または大学施設を右往左往するのに十分な軽さです。

LFAの見解

TDP 0は、平らな作業場があるほとんどの場所で簡単に低コストの錠剤を量産できる賢いエンジニアリングの一端です。使用しない時のために極めて保管しやすくコンパクトな設計ですが、それでもなお非常に効果的に動作します。安定性があり、手動を錠剤化の圧力に変換するという極めて効率的なこの製品は、大型機械が収まらないコストや場所で小規模の錠剤化に適している打錠機です。それでも、強くて壊れにくい素晴らしい錠剤を製造します。

| 名前 | 値 |

|---|---|

| ダイ数 | 1 |

| 製造能力 | 30-50/分 |

| 錠剤の最大直径 | 10 mm |

| 錠剤の厚さ | 2-6 mm |

| 最大圧力 | 3.1 kN |

| 充填臼の数 | 1 |

| 二層錠の可否t | いいえ |

| 総重量 | 30 kg |

| Net Weight | 24kg |

How Much Profit Will This Machine Generate?

Are you able to calculate the amount of profit your business generates per tablet? If so, this calculator will be able to tell you how many hours you will have to run this tablet press to cover its investment.

It will also be able to tell you the amount of profit it will generate every hour you run this tablet press, which makes this calculator a powerful tool when deciding on which tablet press is right for you or your business.

Profit Generated Per Hour

This machine returns it's investment in hours

Yes, it does not matter what age, size or sex the person consuming the products is. It is, however, important to check the intolerance data.

Yes, the TDP 0 is an extremely simple machine. You will find that you can strip it down and clean it with very little effort.

Yes. Some of them. There are a number of parts that are able to be changed between the different TDP ranges. This includes the tooling, a lot of the upper and lower drift pin assemblies and the boot bolt and spring.

No, the TDPs are not CE certified. To acquire this certification, they would have to be installed in a protective cage, which we do not provide.

No, sorry, that is just is not possible.

Yes, you can, but there are a number of requirements that we need to fulfill first.

You will need to contact our team and provide them with a copy of all of your MSDSs for all of the components of your mix.

We need to have a good understanding of your business and the challenges you are facing.

You will also need to book an appointment with the office that you would like to visit.

For more information please get in contact with the team: https://www.lfatabletpresses.com/contact

Yes. Very easily.

We have free lifetime technical support for all machines sold by LFA.

Just contact us with your machine serial number and we would be happy to help you with any problems.

Yes, the contact surfaces are all food and pharmaceutical safe.

They are made from a combination of, stainless steel, chrome coated brass and the steel used for your tooling (often S7).

As such they are all compliant with most rules for food or pharma manufacturing.

We strongly recommend that you check your local laws as these do vary from state to state and country to country. If in doubt reach out, and we will be happy to find out.

Yes, you can.

You are able to make any shaped tablet up to the maximum diameter of this tablet press which can be found under the "specifications" tab.

We are able to customise tooling to include lettering, numbering and logos. If you would like customised tooling please fill out our custom tooling form: https://www.lfatabletpresses.com/custom-tooling-form

Yes. You can order custom tooling here

Technically you can use multi-tip tooling with the TDP0, but as the maximum diameter size is 10mm, all of the punches would have to fit into this space resulting in very small tablets. They would have to be around 3-4 mm because below this they would be too small and above this, they would be too big. On top of this multi-tip tooling is incredibly expensive. It would be worth buying a DTP 25 for this type of tooling.

Yes, you can, but we do not sell larger hoppers. Also, since this machine is operated manually, it might not be helpful because of the time it takes to empty a full hopper of powder. Because of this, we recommend refilling your hopper as you go to avoid particle separation.

Yes, the TDP and RTP range all have a weight adjustment for it.

on the TDP it is the bottom of the two cogs on the lower drift pin assembly.

Here is a link to a video showing you how to tune up the TDP 5: https://www.youtube.com/watch?v=4dTscUdRJzQ

Here is a link to a video showing you how to tune up the RTP 9 or the RTP 118: https://www.youtube.com/watch?v=YJFt5AFJ1hw

It is important to know that the exact weight of each tablet will vary from tablet to tablet.

A well-homogenized mix that has a consistent granule size should be able to achieve an accuracy of +/- 3% or less.

It is important to know two things:

Firstly, TDP Universal Tooling came into effect in 2018. Machines brought from LFA before this time may be slightly different sizes. We always recommend checking the size of your tooling before placing your order.

Secondly, a number of companies make unofficial TDP tablet presses.

They do not always conform to the same sizes, tolerance or quality as LFA TDPs or tooling. If you bought your press from someone else other than LFA, we are not able to guarantee that our tooling will fit.

Yes, you do get a die with the machine. Every machine comes fitted with a die.

If you would like you can get this customised with your logo or lettering but it takes 6-8 weeks.

Or, we have a standard 8mm round, bevelled edge with breaker installed in the machines in stock.

That depends on the country you are located in.

In the EU and UK no. You do not need anything to buy the press.

In the USA we have to file a piece of paperwork with the federal government when we sell the press.

We, however, do all of this paperwork for you and do not need to do anything.

The only countries that require a license, as far as we know, are Canada and Australia.

If you are located in Canada then we recommend that you contact Health Canada prior to placing your order. Details regarding the import process can be found at the following link: Importing and registering pill presses (designated devices)

The document you need to fill out and file for a purchase originating in Australia is called a B712. This can be found at: https://www.abf.gov.au/form-listing/forms/b712.pdf. If you would like to speak with one of our team about this, then please get in contact.

The TDP 0 does not have to be bolted down, but we highly recommend it. The machine does not come with bolts, but this can be determined based on the thickness of your work surface.

To calculate the length of the bolt required, first measure the thickness of your surface, and then add 35 mm for the thickness of the TDP 0 base and the thread of the nut and the washers. You will then need to order 4 x M6 bolts in the length that you calculated, as well as 4 x M6 nuts and 8 x M6 washers.

This will be all you require to bolt down the press securely.

No, it does not need to be bolted into position but we do recommend it. If the machine is not secured in position by bolts or another method then it is more likely to shake a bolt loose, resulting in varying tablet weights. On top of this, the vibrations are likely to make the machine sound louder.

The machine does not come with bolts because we do not know the thickness of your surface.

This is a hard question as it is done on personal strength and the pressure is adjustable. If you think about it, it is as hard as possible before you can't make the rotation any more. This is the same as a TDP with a motor, the max pressure is as much as the motor can exert before the press jams.

The upper drift pin assembly is used to adjust the pressure. You can watch a video on this here: www.youtube.com/watch?v=pc2gfDU3NiQ

Here is another video which tells you how to set up a TDP ready to press: www.youtube.com/watch?v=4dTscUdRJzQ

The TDP can operate as long as the user can rotate the arm on the machine.

We have been able to get speeds of around 30-50 tablets per minute, but the machine will only run for as long as you have the energy to keep it turning.

It is hard to keep up 30-50 tablets per minute for long.

If you need to make more than this then we recommended the TDP1.5 or TDP 5.

We would recommend cleaning down the machine and leaving it re-greased after every use. This will ensure the longest life possible.

Here is a video on cleaning the TDP 5.

When greasing the machine, avoid getting any grease near the tooling or pressing surfaces, as this will get into your tablets and affect your powders.Grease the top cam well, then apply a small amount to the upper drift pin assembly and the lower timing rod.

More information on greasing your machine can be found here: TDP 5 Lubrication Schedule

This is a common question, and we have tools to help you:

A video on the differences between the different TDP's - www.lfatabletpresses.com/videos/tdp-range

The Right Machine For You Questionnaire - https://www.lfatabletpresses.com/tablet-press-questionnaire

These will explain the different machines, and give you a much better idea. If you are still unsure, please do reach out, let us know what you are making and the quantity, and we will help to guide you through the process.

In order to determine whether or not your machine is still under warranty, you will need to call or email the office the machine was purchased from, and provide the serial number.

It is a very sturdy machine. However, if it arrives in less than perfect condition, please contact us and we will make sure to get you back on track.

Yes, this could be down to corrosion or due to oxidation of your product. We would highly recommend taking your tooling out of the press and cleaning it at the end of every production run.

We would also recommend polishing the tooling to keep the surfaces clean and less likely to cause picking or capping.

Yes, this can happen because the boot bolt and spring have been screwed too far into the press or have not been screwed in far enough. It is important to make sure that the bolt is in the correct position before over tightening the set screw.

It should be pointed out that it will not affect the operation of the press if it is damaged.

This will depend greatly on the products you are pressing. If you are making food or pharmaceutical products, then you are going to need food or pharmaceutical safe cleaners.

When you clean the machine, make sure that it is completely dried and oiled afterwards to avoid any rusting of key parts.

More information on cleaning and maintenance for the TDP 0 can be found here:

These gears are known as cogs and are used to tune the press by setting the tablet weight and ejection height. The upper drift pin assembly is used to adjust the pressure.

You can watch a video on this here: Setup the Fill Depth, Punch Pressure & Ejection Height on a TDP 5 Tablet Press

The ideal condition for manufacturing tablets using the TDP 0 is a cool, clean, and dry environment. For the best results, we recommend using directly compressible or granulated powders.

This is a very common question as all of the machines are extremely similar but equally have different strengths.

The easiest way to split these up would be into automatic and manual machines.

The TDP 0 is the manual model and requires you to turn the handle on the side to produce the tablets. This has the least amount of pressure and is the entry-level model in to the TDP range.

The TDP 1.5, TDP 5 and TDP 6s are all automatic machines that are driven by an electric motor.

The TDP 1.5 is the entry-level model in to the automatic machines it has the least pressure at 15kn it is also limited in the size of the tablets it can produce.

The TDP 5 is our most popular model and can produce approximately 5,000 tablets per hour. The TDP 5 had 50kn of pressure and can produce tablets up to 22mm in diameter.

The TDP 6s is the top of the range machine and is more suited to irregular shaped tablets. The TDP 6s also has slightly more pressure at 60kn and is better suited to certain products that do not form tablets as easily.

To get a recommendation on which one will best suit you or your business, take the quiz here www.lfatabletpresses.com/tablet-press-questionnaire

The length of the warranty on any of the TDP range machines is 1 year from the date of purchase.

This warranty covers spare parts and excludes tooling and maintenance labour from LFA for machine services.

When you receive your machine, you will be given a serial number that will also be stamped onto the press. You will be able to use this if you ever need to make a warranty claim.

Full details on the LFA warranty can be found here: Warranty | We Have You Covered

The maximum pressure of a TDP 0 is 3.1 kN.

The maximum tablet diameter possible on a TDP 0 is 10 mm, but this will vary depending on the properties of your tablet mix.

This will really depend on the bulk density of your tablets. Watch this video for more information

The best way to describe this is with a trick question: What weighs more, a ton of feathers or a ton of lead?

The answer is neither since they both weigh a ton, but their dimensions are different. This is the same with powders. You can have some that are like sand and some that are light and fluffy, so compressing them to the same size does not always mean that you will yield the same weight results because their particles hold weight differently.

The TDP 5. Hands down, this has been our most popular model for a while now. We do get customers coming back and upgrading to the RTP 9 (normally after a couple of years), but most new customers initially choose the TDP 5.

"The machine is made from a number of materials. The hopper is made from sheet steel, the tooling is made from S7 steel, the boot is cast from brass and has a chrome plate coating, the base is cast from FC250 and coated in an enamel paint. "

As with any tablet press, it is good to have a particle size of around 80-60 mesh.

This would be large enough to avoid large losses and small enough to flow well through the machine. If the powder is finer than this then you are going to experience a larger level of loss.

If the particles are larger than this then it might not flow through the machine well and get caught as it is trying to enter into the die bore.

This being said every powder is very different and you will need to do tries to work out what is best for them.

We would recommend using goggles, a dust mask and gloves at a minimum, but you may require a lot more depending on the products that you are working with, and your local health and safety laws.

Get a capsule filler.

You will not be able to make tablets.

Click here for more information https://www.lfacapsulefillers.com/

There are a number of ways we are able to support you:

- Every machine comes with a full manual that is emailed to you after purchase.

- There is a large range of video tutorials to teach you how to use the press.

- The machine comes with lifetime technical support. You can call, Skype or email to get answers to your questions and problems.

If after all of this you are still struggling to use your press, we are able to come to you. This is a service we charge for.

More information on this can be found here: https://www.lfatabletpresses.com/services

We recommend a strong and sturdy table that can hold more than 24 kg, since you will also be operating the machine on it. It is useful if you can bolt the machine down or use a set of clamps to secure it in place.

All of our machines are made by us in Taiwan, and are shipped to you from our nearest office.

We have offices in the UK, USA, Germany and Taiwan.

Because they are made by us, we are able to control quality and give you the best support possible. And because they are shipped from your local office, wait times are reduced and customs clearance is avoided, ensuring you have support in your time zone in a language that is convenient to you.

The most common part to wear out on the machine is the boot. This comes in direct contact with the die cavity and can be hit or chipped by the upper and lower punches. This is made of brass so that the tooling is protected in the event of a collision. Because of this, the boot is soft and will wear over time. If anything, we recommend keeping a spare to avoid losing production time.

We also recommend that you keep at least 1 spare set of tooling as this can break or wear over time.

LFA aims to hold all major spare parts and tooling in stock so that they are ready to ship out in the event that you need them. The lead times on sold out parts, however, can take up to 6-8 weeks

There are a few interchangeable parts if both machines have been made by LFA Machines. From the TDP 0, this includes the tooling, the lower drift pin assembly, and its corresponding set of cogs.

The most important fit to check for is tooling that you may have previously purchased, because the base plates have been redesigned to fit the universal standard tooling die.

More information on the TDP Universal Tooling Standard can be found here: Tooling | Punch & Dies for TDP Pill Presses

All other parts are custom to this press.

Yes, some parts are interchangeable if both machines have been made by LFA Machines. The upper drift pin assembly and the lower drift pin assembly will fit.

The most important fit to check for is tooling that you may have previously purchased, because the base plates have been redesigned to fit the universal standard tooling die.

More information on the TDP Universal Tooling Standard can be found here: Tooling | Punch & Dies for TDP Pill Presses

There are three reasons to granulate your formula:

1. To improve the flowability of your formulation.

2. To make your formulation more compressible.

3. To ensure a consistent spread of API throughout the formulation.

If you would like to find out if your mix needs granulation then we do have a tablet formulation service available.

You can find out more about the tablet formulation service here: https://www.lfatabletpresses.com/services

TDP ツーリングStarting from 特別価格 $139.99

TDP ツーリングStarting from 特別価格 $139.99