The Different Types of Tablet Press Tooling

Introduction to Tooling

The fact that there are different specifications of tooling, and then different standardized sizes in the specifications, that sometimes have the same names, can be very confusing.

At LFA we can currently provide 4 types of tooling, TDP, RTP, TSM and Euro.

Let's look at these one by one.

TDP Tooling

TDP Tooling is specific to LFA machines. We use it in our single station tablet presses.

TDP tooling from one type of TDP press can fit all of the other TDP’s in the range. This means if you upgrade from a TDP 0 to a TDP 6 your tooling is not wasted.

We have also developed the VICE Handheld Tablet Press to use TDP tooling. This way you can move from R&D directly to small batch production with limited down times and reduced costs.

While TDP tooling is able to change from one type of TDP to another it is not able to fit into rotary tablet presses or any of the LFA’s RTP range.

RTP Tooling

For the Rotary Tablet Presses we have to use one of the other types of tooling, RTP, Euro or TSM. All of these are what is considered a rotary tablet press tooling however all of them are built to different standards.

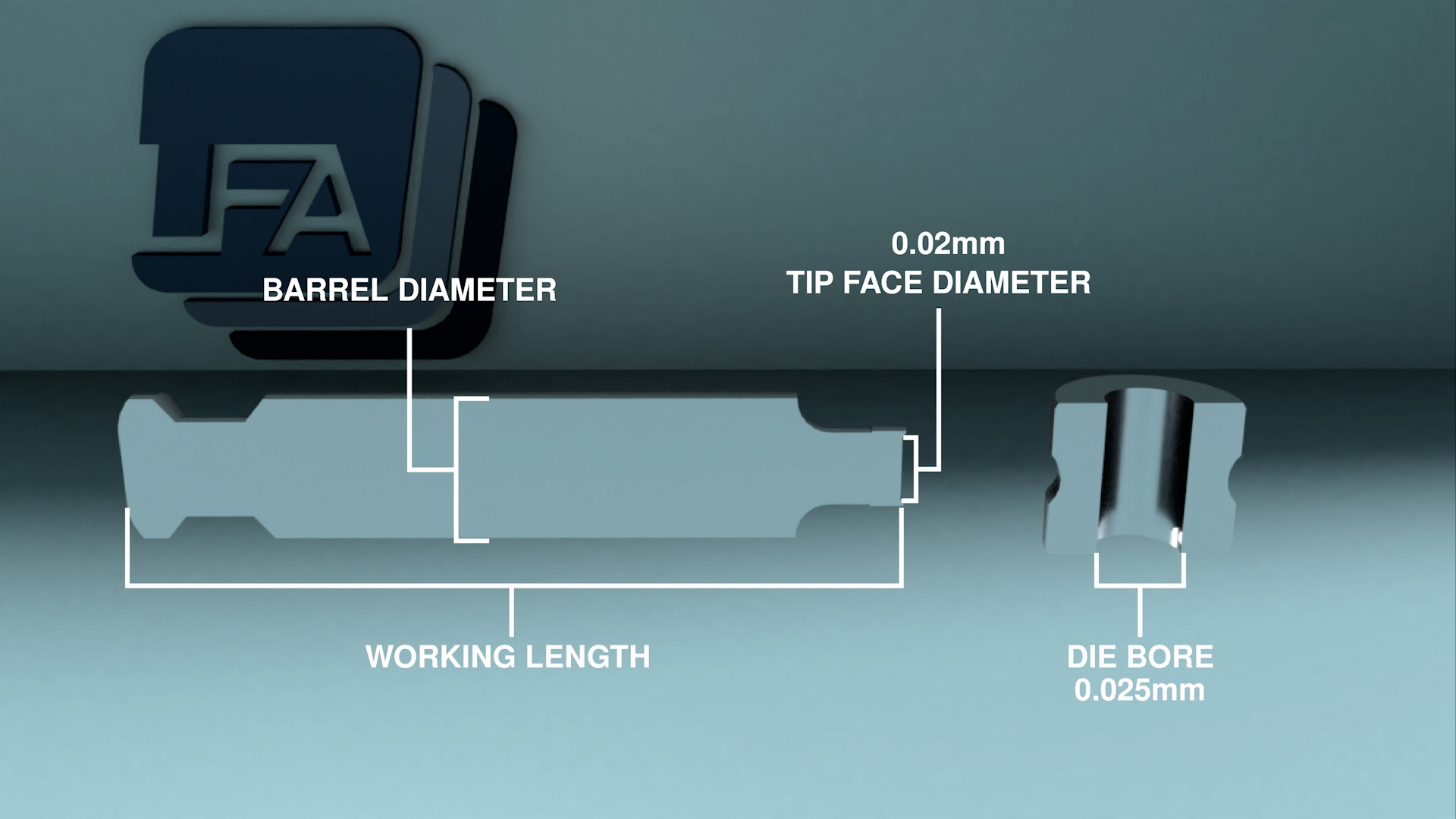

The RTP Tooling is unique to LFA machines and is machined to tollarances defined in ISO 2768-1 except in 4 critical places:

- The working length, the barrel diameter and the tip face diameter where we manufacturer to ±0.02mm

- And the die boer where we manufacturer to ±0.025mm

TSM Tooling

TSM (Tooling Specification Manual) is a manual written by the American Pharmaceutical Association. Even if your press is not set up to take TSM tooling, we would really recommend that you buy a copy of the manual as it has a number of extremely helpful sections for tablet press owners and operators.

The TSM tooling specifications are all given in inches or imperial measurements. As such it is predominantly used in the USA.

Finally there is what is often referred to as Euro tooling. This is based on the ISO 18084 standard.

While the TDP and RTP tooling only have one size. Euro tooling and TSM tooling have 2 common sizes and 4 majorly accepted sizes. These are known as B, D, BB and DB, with B and D being the most common.

Where it can get a little confusing is that the TSM and Euro specifications both refer to there tooling sizes as B and D. So if your buying a tablet press and the listing says that it is set up for say “B tooling” it is really important to ask under which specification.

The difference between B, D, BB and DB are important when considering the size of the tablet you wish to make, we will cover this in a different video.

The main way that tooling is different, is in the following dimensions:

- Working length, barrel diameter, die diameter and die height

- Working length is from the head flat to the lowest point on the cup face.

- Barrel diameter is the diameter of the upper and lower punch barrels.

- Die diameter is the diameter of the die bore and the die height is the overall height of the die bore.

Here is a table of the differences:

|

Tooling Specification |

Tooling Size |

Working Length |

Barrel Diameter |

Die Diameter |

Die height |

|

TDP |

42 mm |

10 mm |

37 mm |

22 mm |

|

|

RTP |

115 ±0.02 mm |

22 mm |

26 mm |

22 mm |

|

|

Euro |

B |

(133.6 - f) ±0.01 mm |

19 mm |

30.16 mm |

22.22 mm |

|

D |

(133.6 - f) ±0.01 mm |

25.35 mm |

38.1 mm |

23.81 mm |

|

|

BB |

(133.6 - f) ±0.01 mm |

19 mm |

24 mm |

22.22 mm |

|

|

DB |

(133.6 - f) ±0.01 mm |

25.35 mm |

30.16 mm |

22.22 mm |

|

|

TSM |

B |

(5.250 - f) ± 0.002 inch / (133.35 - f) ±0.05 mm |

0.784 inch / 19 mm |

1.1875 inch / 30.16 mm |

0.875 inch / 22.22 mm |

|

D |

(5.250 - f) ± 0.002 inch / (133.35 - f) ±0.05 mm |

0.998 inch / 25.35 mm |

1.5 inch / 38.1 mm |

0.9375 inch / 23.81 mm |

|

|

BB |

(5.250 - f) ± 0.002 inch / (133.35 - f) ±0.05 mm |

0.784 inch / 19 mm |

0.945 inch / 24 mm |

0.875 inch / 22.22 mm |

|

|

DB |

(5.250 - f) ± 0.002 inch / (133.35 - f) ±0.05 mm |

0.998 inch / 25.35 mm |

1.1875 inch / 30.16 mm |

0.875 inch / 22.22 mm |

|

|

"f" = the cup depth |

|||||

As you can see the Euro and TSM are very close in comparison. We are from time to time asked if they are interchangeable, and while the answer is yes in some circumstances, we recommend against it as it involves calibration to account for the small differences in working length, especially for things such as ejection cams which may need changing.