Tablet Tools – How To Check and Measure Your Tooling

It is time consuming and expensive for tablet manufacturers to inspect tooling equipment. That said, advancements in technology have made in-process inspections easier to carry out. Here we discuss some of the main technological developments that have facilitated an easier and less costly in-process inspection.

When inspecting tablet-tooling equipment, manufacturers are faced with several challenges. The process can be time consuming and the expense means that some manufacturers cut back on the number of inspections or eliminate the process entirely. This is an issue that needs to be addressed; the quality of the tooling equipment will have a direct impact on tablet quality. Even though the equipment might be running smoothly, if the tooling has wear on it, the quality of the tablet will be affected. The only way to ensure overall quality of the tablet is to inspect the equipment for wear and defects on a regular basis.

Keeping inspection records is also important. In some companies, the data is recorded, filed, and never seen again. Recent advancements however allow companies to file their data efficiently on a computer, making the record-keeping process simpler and the files more easily accessible.

Tooling Inspections

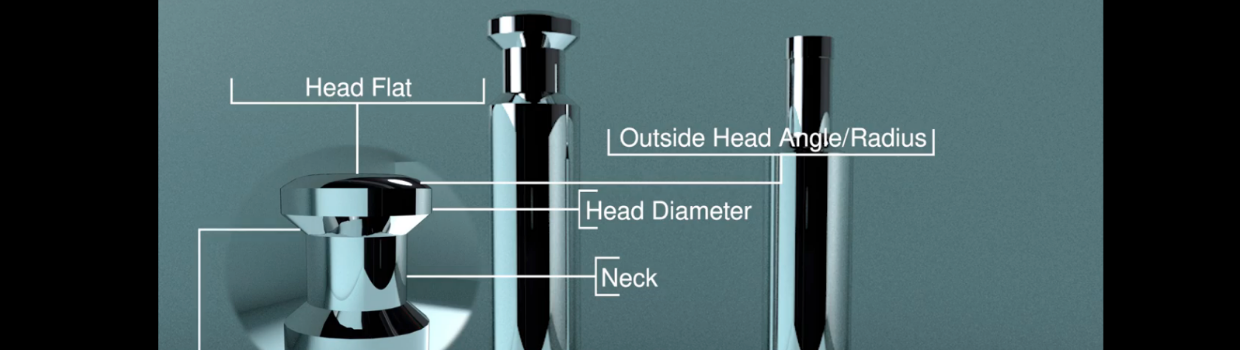

A common misconception amongst tablet manufacturers is that they must inspect the equipment in the same way that tooling manufacturers would. A tooling manufacturer must inspect the overall specification of the equipment to ensure that it conforms to the industry’s standard. This is not the case with tablet manufacturers. The tablet manufacturer only needs to inspect a few essential parts like key wear areas – usually the working length of the punch and the cup depth. There is little point in inspecting other areas, like the barrel diameter, overall length and tip dimension, because they either do not change or are impossible to inspect accurately.

Iscriviti alla nostra newsletter

Punch Working Length Dimension

The working length of a new punch will be different to the measurement of a worn punch. Unlike other areas, the working length tolerance applies to the punch only when it comes together with the other tools in the equipment. The working length is graded on a curve. For example, if a new punch were designed with a 5.230 inch working length with a 0002 inch tolerance range, each punch would have a working length of between 5.299 and 5.231 inches. Worn out tools can wear to less than 5.229 inches but still be within the 0.002 inch range. The key area is the total range of 0.002 inches, which has a working length tolerance of +/- 0.001 inches.

Tooling equipment might have working lengths of 5.228, 5.227 or 5.226 inches, which all are below the lower limit of 5.229 inches for a new tool. The dimensions are however within the limit of 0.002 inches. Calculating the working length and the tolerance manually can be time- consuming and difficult; using a computer however, makes the process much faster and more accurate. It is not recommended that the first punch be used as basis for measurement since the condition of the first punch is not determined and may vary from one punch to another. This would be a waste of time and effort if you were to find out later that the first punch was not on par with the rest of the punches.

Entering data can also present problems; one way of overcoming these is to capture the information and process it directly in the computer’s database. The most common way to achieve this is with the use of a USB, which is activated through a foot pedal or button. This way, the data can be transferred directly to the computer and the transfer stopped easily (with a foot pedal). This reduces the likelihood of typographical errors, which can be an issue when dealing with measurements. Some systems can also communicate and synchronize with other software, making it simpler to input data without the use of foot pedals or buttons to capture the details needed.

Storing data electronically will allow for easier retrieval of information for a review or further analysis. Results that have different tolerances can be reviewed and compared with other reports, making it simpler to check and identify any inconsistencies. This automated approach makes is much easier than viewing the reports manually. Information such as the average, minimum and maximum, and range differences can be added as well. The automated system can compare reports from several inspections.

The automated system can also be used during tool matching. Here, the data already collected can be used to generate reports that might be difficult to provide when conducting a manual inspection. Matching is important as it allows the tablet manufacturer to lower any deviation in the tablet’s thickness and hardness. Matching is achieved by sorting the upper and lower punches based on the longest and shortest sequences. If the previous data is already stored electronically, the result can be available in a matter of seconds. It takes much longer to process the data manually and uniformity may not be established.

The potential to access an inventory of the company’s entire tooling equipment is another advantage with using technology. Data can be easily shared between tool manufacturers and tablet manufacturers without the timely process of manual entry; the database will already contain the information on each piece of tooling equipment as well as inspection data. This method also eliminates the need to re-enter any previous information.

Laser Technology

The advent of laser technology allows inspection without any intervention on the part of the inspector. Laser devices can be integrated for just a small cost, allowing for non-contact inspection. With this addition, inspection can be undertaken without any direct contact with the tooling equipment, some of which have sensitive tips that are easily scratched or marked. The laser can measure the cup’s depth without the risk of damaging the tip-face of the equipment. A simple press of a button would activate the laser and the value collected will be recorded instantly. Some lasers are powered electronically, which can reduce operating expenses such as the need for supporting equipment (e.g. compressed air).

Unconventional Ways To Monitor Tools

There are alternative methods for monitoring the wear of tools aside from inspecting the tool itself. One way to do so is to track the number of tablets manufactured by a set of tools and use the historical data for comparison. If, for example, the historical data states that the tools have a produced 1M tablets on average and at present the tool is producing 800,000 tablets, then the tool wear can be recorded as 80%.

A database that has the capability to record the tool use and compare it with the total estimated yield makes it even easier to monitor tool wear. The information can also help give the manufacturer an idea of what tools are going to need replacement and which tools to keep in a backup selection. Correct forecasting allows tablet manufacturers to contact the tool vendor and request the required equipment in good time.

Other tool control information obtained from the inspection can also be useful. Entering data in the form of drawings, for example, makes it easier to track and maintain tool specifications and provides a visual for any changes in the care procedures.

Multi-tip Tooling Inspections

Multi-tip tooling is relatively new to the market and as such, presents new challenges – especially when it comes to inspection guidelines. As the equipment has several tips, punches, working lengths and overall lengths, the chosen software must differentiate between the data for each tip. The ideal method of tool matching for multi-tip equipment is to measure the working length for each tip and average the values of the combined working length for the punch assembly. The average of each upper length working length can then be matched with the corresponding average length of the lower punch during the tool matching process. It is possible to match one tip to another individually, but this would be much more time consuming.

Digital Technology

The advent of digital technology enables pictures to be taken of the equipment during the inspection process. The pictures can be uploaded to the database for reference and can be linked to previous records. They can also be attached to email and even sent to the tool vendor for analysis. The process enables other individuals to check and have access to the information provided by the inspector.

Inspection of the Die Punches

To date, there is no cost effective way to do an inspection of die punches. During inspection, the focus is mainly on the wear points on the die, which are the inner diameter and the die bore. Measuring the inner diameter of round shape dies is easy; measuring non- circular objects however, is more difficult. To measure an oblong-shaped die bore, the minor and major axes must be measured. Measuring the centre line of both the major and minor axes accurately is challenging and could lead to incorrect measurement.

Another wear point area is the place inside the die where the compression takes place, also known as the “wear ring”. Any problem in this area would mean that the die is no longer acceptable for use. One method used by inspectors is called “bore sight”, where any visual ring would suggest dimensional wear. A sensitive deviation indicator can also be used, which would help to determine the die’s functionality. A bore gauge can be useful for measuring the wear ring; however, the effectiveness of this tool may depend on the depth and variation of the die bore. One can also do a visual inspection and look for damages such as cracks, nicks, wear rings and abrasions.

How to Measure the Tip Diameter

It is difficult to measure the tip diameter of a worn punch and as such, in-process inspections are not usually carried out. As wear only happens on the edge of the leading tip, conventional contact measure equipment is ineffective. Using a micrometer to measure the tip straight is not typically effective because the wear is usually difficult to see with the naked eye. This is not the case when measuring a new tip, because these are not worn. The tip diameter dimension is another type of measurement often used by tooling manufacturers, but not usually for in-process inspections of tablet manufacturers. Digital measuring equipment and optical comparators are available to measure the tip.

Security Features

To prevent the corruption of data and protect the database, it is important to include security features. An electronic audit can be used to record previous data before new data or information is added or deleted. Referring to previous data would help to check for any modifications to previous data.

Summary

Changes in the inspection process had long been overdue and thanks to the advent of new technologies, the tooling industry is now ahead. What was once a costly process has evolved, enabling one to collect data and help improve the quality of tablets. A database of tooling information makes it easier to find data and forecast ahead; it also allows users to look back and perform historical analysis. The automation of many processes allows non-contact inspection, which reduces the risk of damage to sensitive tooling equipment. Overall, the use of technology enables tool manufacturers to produce high quality tablets more efficiently.

The pressure that the industry faces helps to promote change. The changes in methods of monitoring, manufacturing and maintaining consistent quality act as evidence that the sector realizes the need for the industry to work more efficiently. The successes and failures of the approaches depend largely on the understanding and knowledge of each one involved.

Although there are still issues when it comes to powders, modern techniques help in alleviating the problems. Understanding the different dynamics involved allows one to better understand the properties that are essential to the process. This approach makes the quantification and measurement of the parameters more efficient. Though to some degree still empirical, this method is superior to relying on manual methods or experience. Current technology allows the testing of different methods with a single instrument, providing ease to access data. The information opens up a world of accessibility significantly aid the process of transferring knowledge and data. It allows people in the industry to study the complexities of the process and develop new ideas and products.